China made Air Flow Type and New Condition wood charcoal carbonization oven making device made in China with CE 008613253417552

| Packaging: | Standard export wooden case or packing wood charcoal carbonization oven making device according to your requirement |

|---|---|

| Brand: | BEDO |

| Place of Origin: | Henan, China (Mainland) |

Basic Info

Model No.: BD-THL

Product Description

China made Air Flow Type and New Condition wood charcoal carbonization oven making device made in China with CE 008613253417552

hot selling

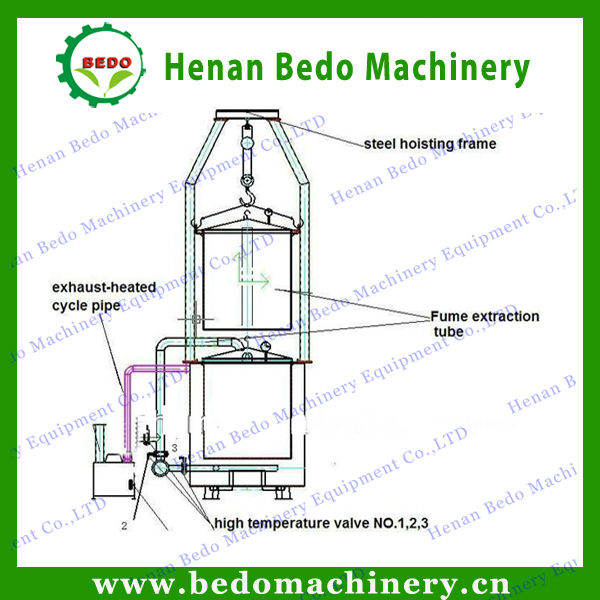

1. Pictures of wood charcoal carbonization oven making device in the woring room

2.The working process of the wood charcoal carbonization oven making device

3. The Technical parameters of the wood charcoal carbonization oven making device

Model No. | THL | DESCRIPTION | wood charcoal carbonization oven making device |

TECHNICAL DATAS & FEATURES | |||

power | exhaust fan (0.22kw, 2 phase,used for discharge the moisture | ||

raw material could be | wood ,coconut shell, wood briquette, bamboo, almond shell, plam shell, | ||

final product | wood charcoal , coconut shell charcoal and so on | ||

capacity | wood (6- 8ton/24hour) wood briquette (9-10ton/24hours),coconut shell (7-8ton/24hours) | ||

operation | one people one shift ( one day two shift) | ||

carbonization time | wood log ( 8-10hours). Wood briquette (8hours), coconut shell (6hours) | ||

energy consumption | 20-30kg firewood or 15kg liquid gas .This type will save 30% payment | ||

The stove include | 3 outer stove,9 inner stoves,3smoking recycle tube, 3 purification tank, 1 five-ton hoisting equipment with E-hoist | ||

introduction of the parts | outer stove | includes heating room (for heating the stove), furnace body and heat-keeping layer (it is made of the heat insulating material, used for keep the heating)

| |

inner stove | Consist of the stove tank body and the sealed top cap. Both of them are made of the heat resistance thermal steel. , and the three carbonization basket can be stack together, easy for loading and transporting ,and it will save a lot of space and transport charge.

| ||

smoking recycle tube | When during the process of carbonizing, there will be some smoke.( can be burning) the smoke can return to the furnace through tube for purifying, after purification , the combustible smoking can be flow into the heating room of the outer stove for heating the stove again, | ||

purification tank | This system is consisting of purification tank and the exhaust-heated cycle pipe. And Smoking purification tank are used for purify the smoking (can not Burning) and filter thewood tar. The smoking through the purification tank will Become water vapor, and it will not pollute the air.

| ||

hoisting equipment | it include the steel hoisting frame and the E-hoist .And it is easy for loading and unloading the stove, and can reduce labor intensity, and it can be avoid the high-temperature burn when lift the carbonization basket | ||

4. The Final products from our wood charcoal carbonization oven making device

5. The specifications of the charcoal from our wood charcoal carbonization oven making device

6. The Application of the charcoal from our wood charcoal carbonization oven making device

3. Remarks:

Carbonizing time: 6-8hours

Cooling type: Natural cooling or forced cooling

Cooling time: 8-12hours(natural cooling)

1.what is the capacity?

One set furnace could deal with around 4.5-5ton raw materials We could do two sets, three sets, four sets connecting together to get higher capacity

2. What is working process ?

It divides into three working process:

A: heating process:

after putting the inner baskets intot the furnace, we need to heat the furnace up to 80-120mins, we could use gas or biomass waste as fuel, when temperature get around 280-330 °C we stop heating

B: Carbonizing process:

after doing the sealing works, the materials inside begin to pyrolysis, it will produce gas at this period, so we need heating in this process, the carbonization time is often around 8-12hours

C: Cooling process:

after carbonizinh, we need to take the inside furnace out, let it cool by natural way, cooling time longer, it is better for charcoal quality

D: After taking the inner baskets out, we need to put another baskets inside, this is the cycling process

if you need this machine , please be free to cotct me :

my phone number : 008613253417552

my skpye number : bedomachinery01

wechat : bedomachinery

whatsapp: 008613253417552

send your Inquiry Details in the Below, Click "Send" Now!

Contact us if you need more details on Wood Charcoal Carbonization Oven Making Device. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Charcoal Carbonization Oven Making Device、Wood Charcoal Carbonization Oven Making Device. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Coal and Charcoal Machinery > Charcoal Stove/Furnace