Home Use Flat Die Wood Pellet Press

| Payment Type: | L/C,T/T,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 20 Days |

| Packaging: | Separate wooden case packing |

|---|---|

| Productivity: | 30sets/month |

| Brand: | OEM/XINGBANG |

| Transportation: | Ocean,Land |

| Place of Origin: | qufu shandong |

| Supply Ability: | 30sets/month |

| Certificate: | SGS,BV,ISO certificates |

| HS Code: | 8474 |

| Port: | QINGDAO |

Basic Info

Model No.: XB568

Product Description

Home Use Flat Die Wood Pellet Press

What is Small Pellet Mill?

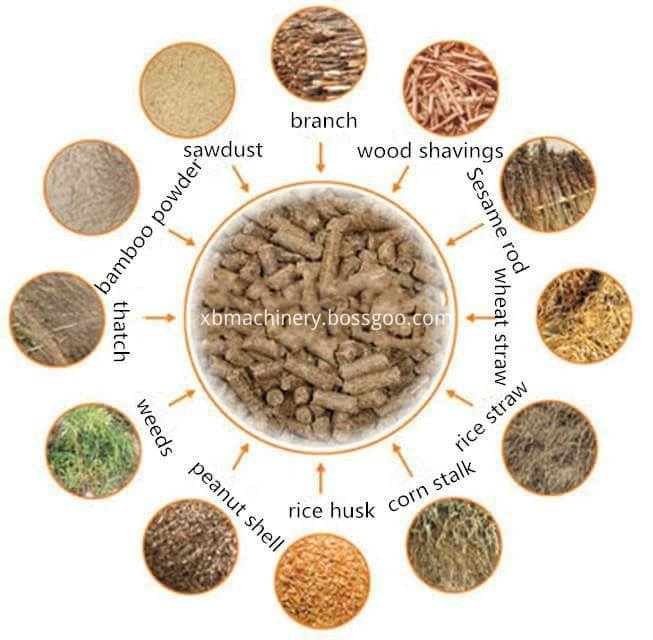

Small pellet mill is also called Flat Die Pellet Mill, which is a small type Pellet Making Machine with small capacity. This pellet machine has two types, D-type and R-type. The two type flat die pellet mill are all good at making wood pellets. Relatively speaking, the yield of D-type is less than R-type. So it is more suitable for processing soft wood raw materials ( like pine wood ). Besides, the investment is lower. R-type is more suitable for harder wood raw materials ( like Oak wood ). From the aspect of structure, the roller of D-type pellet press is fixed on the upper machine and the die rotates with the main shaft. R-type is contrary to D-type, the die of R-type is fixed while the roller rotates.

Advantages of biomass granulator:

Model Power(kw) Output(kg/h) Weight(kg) Packing Size(mm)

XBSP-D 150B 3phase 5.5 50-100 95/110 800*450*700

XBSP-D 200B 3phase 7.5 80-120 200/230 1050*480*930

XBSP-D 230B 3phase 11 120-200 290/320 1180*540*1000

XBSP-D 260B 3phase 15 160-250 320/360 1240*540*950

XBSP-D 300B 3phase 22 250-400 350/380 1300*560*1100

Pre-sales service:

Receive customer consultation, determine the scale of operation according to customer demand, and provide plant construction plan;

Provide customers with project design and process flow design, which is suitable for the formulation of the purchase plan of your machine equipment, and provide customers with relevant technical documents in time.

According to your special needs, design products, train technical operators for you to carry out preliminary design and construction design.

In-service:

We send technicians to the site to guide the installation, commissioning and training of operators

24-hour telephone service throughout the day, holiday service as usual.

After-sales service commitment:

Telephone support means that the customer asks for technical support and help from us by phone or fax when they encounter difficulties in using the equipment or when the equipment is abnormal.

After confirming the customer's service request, we will arrange technicians to help the demander locate the fault within the specified time (i.e. response time) by telephone, and propose solutions, so as to finally guide the customer to troubleshoot the equipment fault.

Field support and failure recovery commitment

On-site support means that the customer asks us for technical support and help by phone or fax when they encounter difficulties in using the equipment or when the equipment is abnormal.

After confirming the customer's service request, if the fault cannot be diagnosed and solved by telephone, we will send technicians to the site to deal with it immediately and finally solve it.

Our products offer "three packages".

One year warranty, lifetime maintenance;

24 hours receiving technical consultation, providing technical diagnosis to customers;

The maintenance personnel shall be in place immediately after receiving the fault notice to troubleshoot the fault;

Assist user system upgrade, equipment and mold update.

Company show:

Shandong qufu xingbang heavy industry equipment co., LTD will build a science and technology leading enterprise integrating research and development, manufacturing and installation, and international trade.

Main development and production of products are building materials equipment: automatic glass magnesium fire board production line, large multi-function wall board exterior wall insulation board production line, fire door core board production line of environmental protection and new energy straw making machine, fully automatic quadrilateral cutting saws;

Woodworking Machinery, automatic cover machine, labeling machine, automatic finishing machine, UV light solid machine, hot pressing machine, vacuum molding machine, cold press machine, universal coating machine, and other products, the above products have passed the relevant state departments of technical appraisal and recognition, has enjoyed good reputation in the market, obtained the customer consistent high praise.

The products produced by the company are sold to all over the country and some surrounding countries and have achieved high economic and social benefits.

Product Categories

Building Material Making Machinery

Compound Ventilation Tube Sheet Metal Production Line

Automatic Four Edge Cutting Saw

Large Fireproof Door Core Board Production Line

Fully Automatic New Compound Straw Tile Production Line

Fire Prevention Board Machine Straw Door Equipment

Fire Prevention Board Production Line

Polyurethane Low Pressure Foaming Machine

Polyurethane High Pressure Foaming Machine

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

Glass Magnesium Fire Board Decorating Plate Production Line

Plastic Extrusion And Recovery Equipment

Plastic Extruder Machine

Plastic Pelletizing Recycling Machine

Sheet Plate Board Extrusion Line

Plastic Washing Recycling Machine

PVC WPC Profile Extrusion Line

Plastic Pipe Extrusion Line

Plastic Crusher & Granulator

Plastic Shredder

Plastic Auxiliary Machine

Woodworking Machinery

Wallboard Decorative Machine

Door Decorative Machine

Cabinet Decorative Machine

Floor Decroative Machine

Moulding Line Decroative Machine

Veneer Machine

Indoor Decroative Machine

Woodworking Wrapping Machine

Sawdust Granulator /Wood Pellet Granulator

Wood Door Vacuum Laminating Machine

Environmental Protection Equipment

Waste Gas Treatment Equipment.

Dust Removal Equipment

Plastic Injection Molding Machine

Plastic Injection Molding Machine

Plastic Blow Molding Machine

Product Categories : Woodworking Machinery > Biomass Granulator